Quickscan

The tool for the optimization of your prefab process

The Quickscan is an ideal instrument to increase quality, improve efficiency and reduce failure costs.

And after all, a good final product costs less in its entirety, provides a better workflow and results in a satisfied customer.

A Quickscan can be performed once as a snapshot, but is particularly suitable for periodically monitoring the quality improvement in a specified period. If desired, safety, sustainability, circularity, energy consumption, or CO2 production can also be assessed additionally.

Benefits

- The Quickscan simply takes place during production (working hours)

- By working together you make use of more than 40 years of experience in the precast concrete industry

- Workable advice that can quickly result in quality improvement, process optimization and cost reduction.

- Exploiting the synergy effect (concrete technology, production processes, quality systems and product requirements)

- Communication for and at every level

- The performance of your production process becomes measurable, so that adjustments can be made concrete and measured.

- Problems can be dealt with quickly and usually easily

- Save costs

- Possible periodic check for insight into progress and/or benchmark

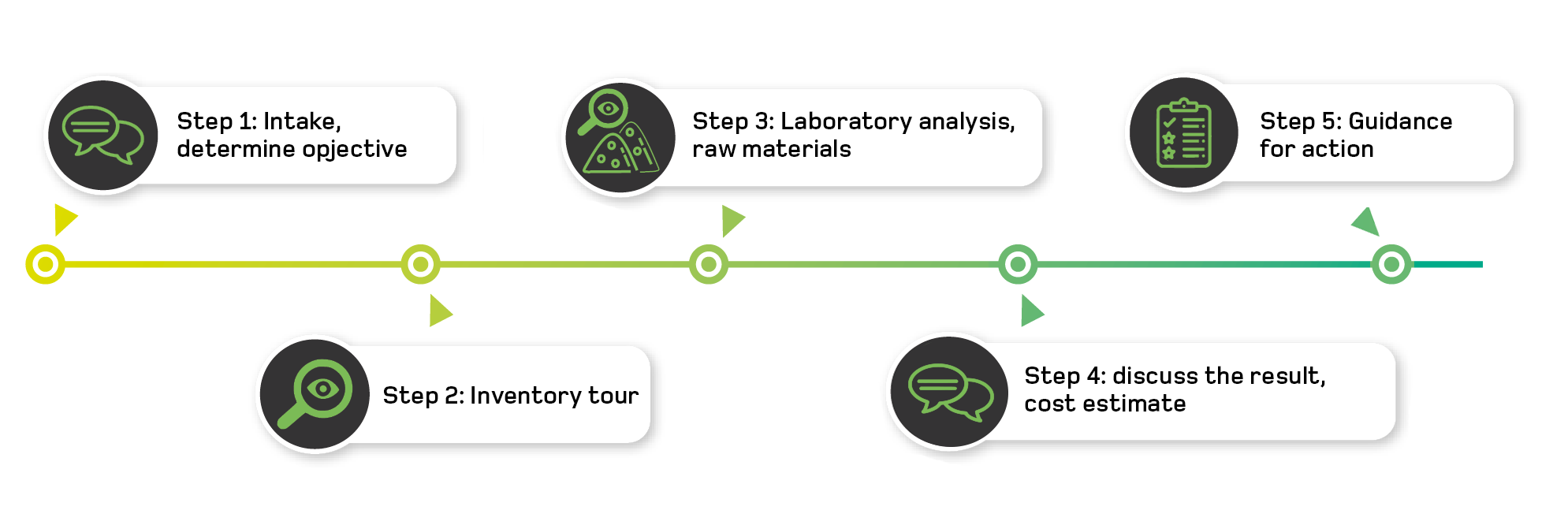

Step by Step process – Quickscan

Intake

Inventory tour

We always start with an assessment of the end product.

Based on this assessment, it is determined which aspects can be optimized to improve the quality of the end product.

Laboratory analysis, raw material

Discussing the results, cost etimate

- Clear analysis and advice with concrete improvement proposals

- Steering together on results

- Discussing the cost estimate and ROI

Guidance for action

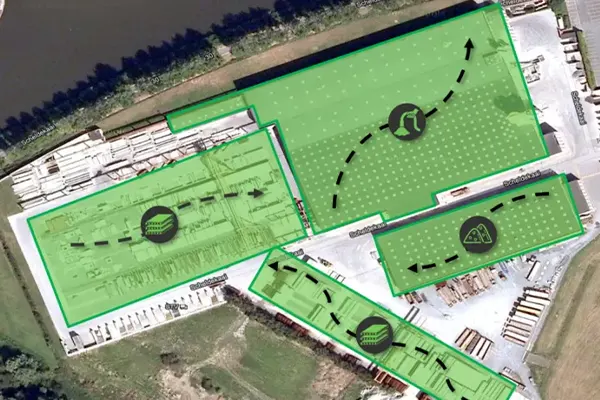

Inventory tour – details

Production & work preparation / Technical screening of the production process

- Internal transportation

- Demoulding

- Harden, Condition

- Depositing, processing, finishing

- Dosing mortar, cube transport

- Mixing, dosing raw materials, mixtures

- Placing insulation, recesses

- Placing reinforcement, lifting facilities

- Molds, magnets, cleaning

Storage inspection - finished product

- What does the storage look like, is it tidy, are there any potential problems that could damage the finished product?

- After that, we will continue to look at the products on the bag field, are there any damages, discolorations, etc.

Reviewing Supply & storage of raw materials

- Quantities, dosing of raw materials, & mixtures

- Post-treatment, finishing, storage

- Research fresh concrete (mixtures), take materialsamples

- Laboratory research

Personal Advice

Result-Advice-Optimization

- Clear analysis and advice with concrete improvement proposals

- Tool for optimization and innovation

- Errors can be addressed early and quickly

- Immediate insight into product quality

- More support through independent analysis

- Steering together on results

- Less (failure) costs

- Better products

- Satisfied customers

- Periodic evaluation with management and production

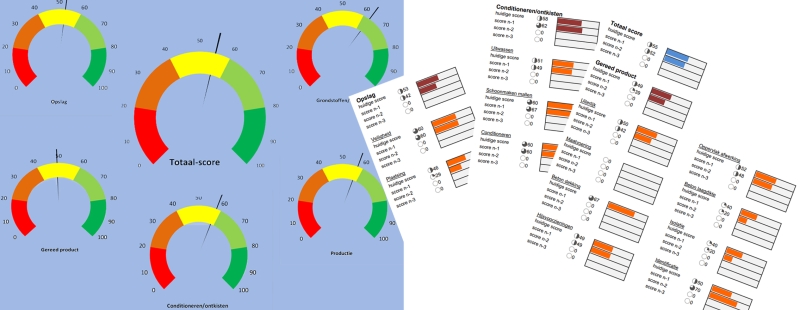

Reporting

- Digital reporting

- The report is available a few days after the Quick Scan

- The report consists of 2 parts: technical information and management information

- Clear reporting based on pragmatical scorecards

- Placing reinforcement, lifting facilities

- Molds, magnets, cleaning

Contact us for further information

“The Concrefy Quickscan is a ideal instrument for quality and improve efficiency and to minimize failure costs.”

Peter Megens

Senior Consultant

T +31 77 8507 222